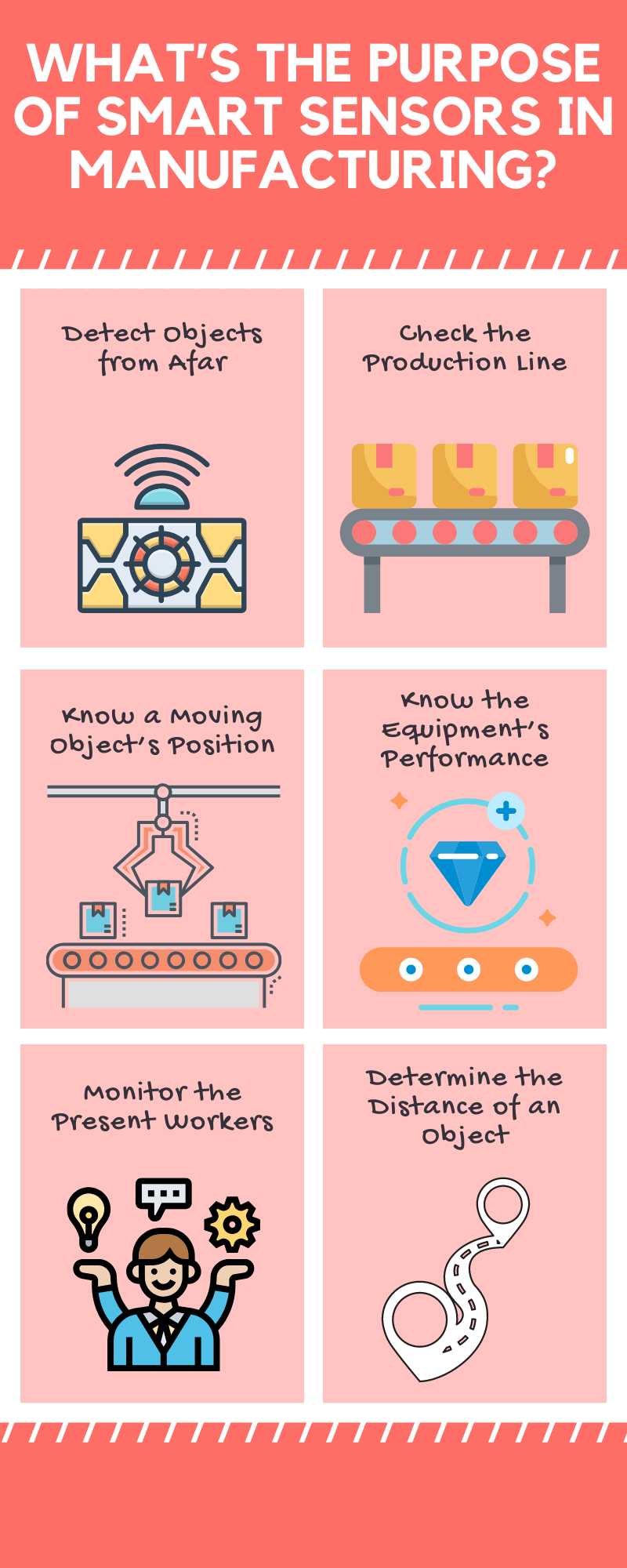

What’s the Purpose of Smart Sensors in Manufacturing?

Two of the common problems that most manufacturers face are warehouse management and daily production line checks. Even though there are overhead cranes and other lifting equipment used to make things more manageable, it is still not enough to arrange the products and materials inside. Thus, you would need to use some smart sensors. Here’s why:

Detect Objects from Afar

Part of these smart sensors is photoelectric sensors. You can use it to see where a specific object is located even from afar. This is useful in warehouses with spacious rooms and massive equipment.

Check the Production Line

Photoelectric sensors can also be used to see if there are defects or missing parts on the goods that are placed on the production line. This is great for maintaining the quality of your products.

Know a Moving Object’s Position

Another kind of smart sensor is ultrasonic sensors. Just like the photoelectric sensors, it can also be useful in production because it can detect the exact position of an object even though it is moving.

Know the Equipment’s Performance

These ultrasonic sensors are also used to know if there is a wire that is about to break in a machine or equipment. You’ll be able to determine if one of these devices will not be working properly and efficiently.

Monitor the Present Workers

Aside from objects, there are smart sensors like inductive sensors that can detect the presence of a person. It’s easier to see if there is a lack of manpower in a particular area if this is the case.

Determine the Distance of an Object

Inductive sensors are also called proximity sensors because they can provide precise data on the distance between two objects. It’s a lot more convenient to use in warehouses that lack space.

You’ll be able to run your manufacturing business more efficiently if you invest in these smart sensors. If ever you need to purchase these, then check out Pepperl+Fuchs Asia now!

Resource: